Processing Line

Food Safety and Security

By providing our customers with safe and secure products based on thorough hygiene management from the import of raw materials to the export of products incorporating ISO9001, ISO22000 and HACCP, we offer foodstuffs that all can be eaten safely at any time with no anxiety about the aspect of hygiene.

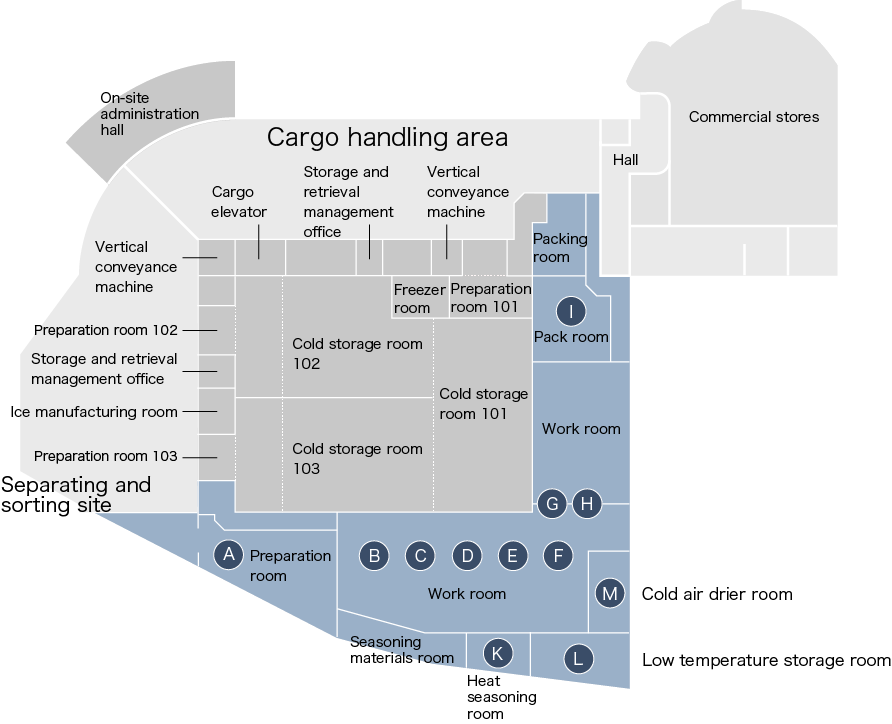

Processing Line Map

ADefrosting room

-

- Fully equipped with blower (air) defrosting equipment. It is possible to defrost using timer settings so there is no burden on the raw ingredients. Defrosting capacity is up to 1.5 tons at one time.

Click for details

BTank lifter, carrier conveyor

-

- After defrosting, products are moved to the tank lifter and drained of water, then they are sent to the water pressure for scale remover on the carrier conveyor.

Click for details

CWater pressure shower to remove scale

-

- Scales are removed by a water pressure shower. There are no damage for not only delicate flatfish but varieties such as Pacific Ocean perch. Water pressure can be adjusted and it is possible to remove scales properly.

Click for details

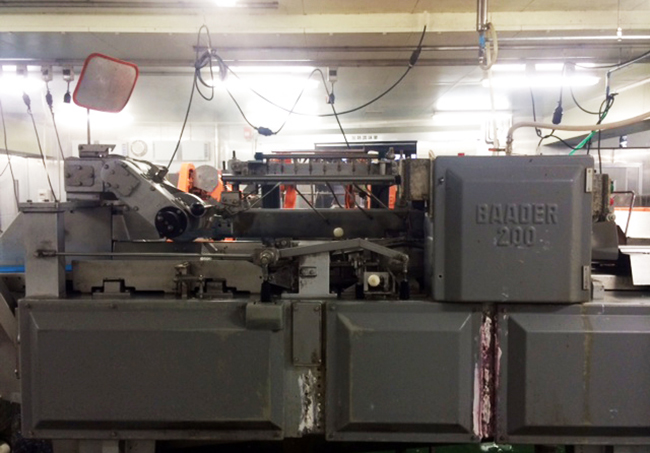

DBaader machine

-

- Cutting all fish sizes from small to large one at very quickly.

Click for details

ETwo-level shaping conveyor

-

- Fish brought on bottom conveyor will be processed by hand, then final product will be placed on the upper level conveyor to the next processing

Click for details

FCarrying roll conveyor

-

- Final fish product is sent to the tunnel freezer.

Click for details

GTunnel freezer

-

-

High-speed tunnel freezer. Lowest freezing temperature is up to -40°C and the length is 14m.

The freezing capacity per an hour is 500kg.

Click for details

HSeparating shutter

-

- Hygienic areas and contaminated areas are completely separated by immediate moving shutter.

Click for details

IAuto-checker with metal detector

-

- Frozen products are passed through a metal detector and automatically flow to 5 different pockets with weight settings. These weight settings can be set at 1g intervals.

Click for details

JPacking room with metal detector

-

- After casing up inside the room, each cases will be passed through the metal detector once more to preventive for any hazards.

Click for details

KHeat cooking room

-

- Creation of ownl flavors with 2 different steam boilers.

Click for details

LCold storage

-

- Fresh fish and pickled fish are stored at chilled temperature condition.

Click for details

MDrying room with cold temperature

-

- Production capacity is 2 tons at one time.

Click for details

Other Equipment

Head cutter

Medium size of filleting machine

Large strapping machine

Large machine of cutting bone

Medium machine of cutting boner

Skin off machine

Cleaning machine by water-pressure